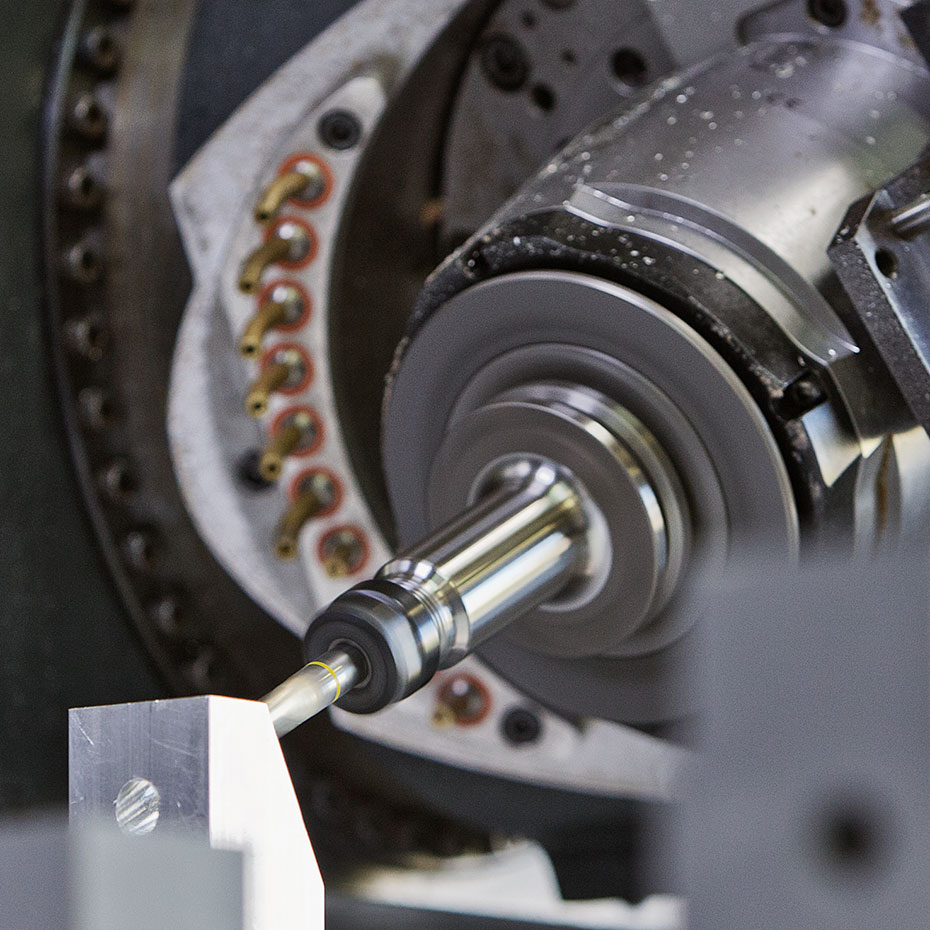

DMF 360

Our new piece of equipment, a DMF 360 by DMG MORI SEIKI, features a rigid machine bed and thermo-symmetrical traveling column, making it ideal both for heavy-duty machining as well as dynamic 5-axis processing.

The DMF 360 is precision milling machine featuring five-axis operation for workplaces with a diameter of u to 1400 mm on an NC rotary table (maximum load 1200 kg). The B axis can be adjusted up to +/- 100 degrees.